Ideal partner to optimize your fashion production

Shoes & Footwear

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Leather Bags & Goods

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Furniture & Upholstery

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Automotive & Aviation Interiors

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Leather Jackets and Gloves

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Saddlery & Sports Textiles

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Safety Suits, PPE & Technical Textiles

Pattern Digitizer, Hide Scanner, Leather Nesting, Die Less Cutting & Automation Solutions

Optimize your Fashion Production through Automation.

GANI ROBOTICS is hybrid software and hardware company with a vision to help fashion tech factories to attain sustainable production. We primarily design, manufacture and implement vision based solutions for Footwear, Apparel, Technical Textiles, Upholstery and Automotive Interior Manufacturing Industries.

Our activity includes research, development and implementation of software, hardware package and offer integrated workflow solutions across units such as warehouse, cutting floor and production rooms. We work closely with industries to recognize their workflow and provide customized solutions to suit their requirements either by implementing from scratch or retrofit in to their existing process routines.

Ahamed Muqthar

Founder, Gani Robotics

Our Products & Solutions

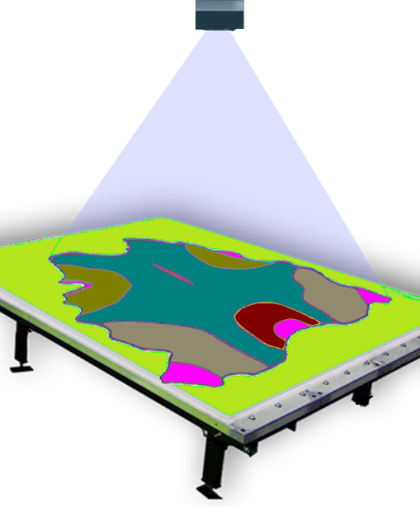

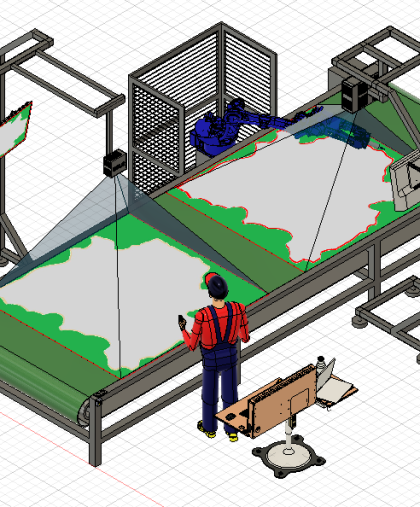

GaniScan – Leather Scanning Machine

GaniNest – Leather Nesting Machine

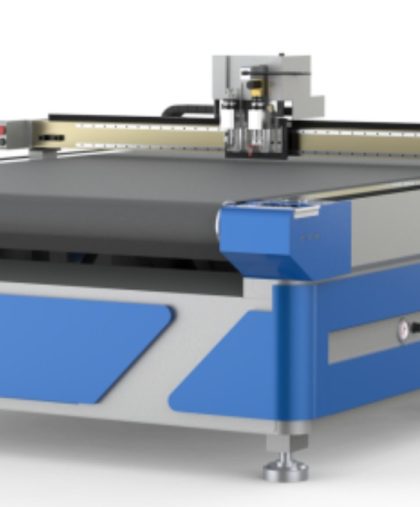

GANICUT – FLATBED KNIFE CUTTING MACHINE

GaniPattern – Pattern Digitization System

GaniMach – Leather Measurement System

GaniDB – Leather Inventory System

GaniGrade – Leather Grading System

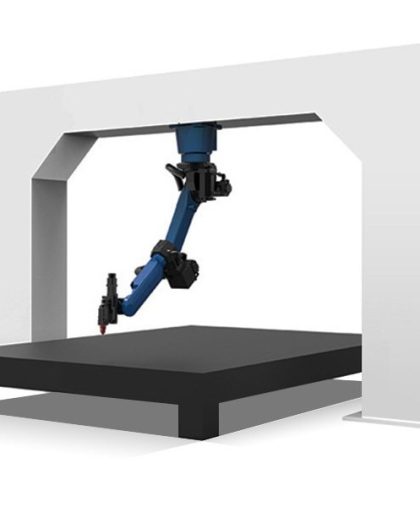

GANIARM – ARM ROBOT KNIFE CUTTING MACHINE

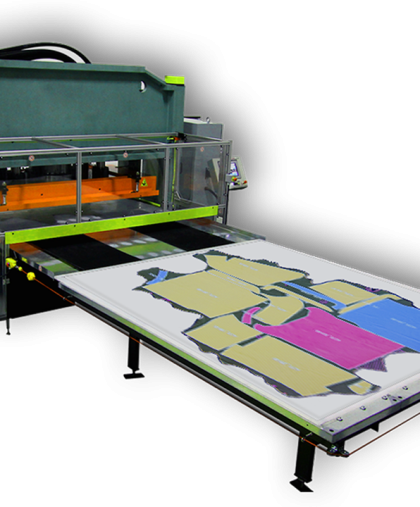

GANIROLLER – Roller Press Cutting Machine

GaniProjection – Hide Projection System

GANIROUGH – Shoe Roughing Robot Cell

GANITRIM – Leather Edge Trimming Robot

Find Out More About Us

With over 25 years of experience under our hard hat, we closely work with industries to build high-quality solutions. We strongly believe that industrial automation is not a mere replacement of the operator but that it must bring an added value: a reduction in processing times, a qualitative increase, a reduction in the consumption of materials and a management of data and information.

Innovation

We have a curious mindset and challenge prevailing assumptions. Not deterred by challenging tasks and believe that all problems have solutions.

Customer Centricity

When we design and manufacture our systems, we always keep in mind their fields of application, business contexts & the people who will use them.

Dedicated Support

With us, you don’t just get Industry 4.0 automation solutions but unwavering support even long after the project completion.

Recognition

You are with right partner to solve your problems. We are recognised by DPIIT Startup India and won grants & awards for our solutions.

OUR MISSION

We deal in technology with passion and Innovation is our DNA, Efficiency is our target.

Gani Robotics create customized solutions based on the needs of our customers and provide turnkey systems either by implementing from scratch or retrofit in to their existing process routines.

OUR VISION

Our vision is to make Industries in particular Leather and Textile manufacturers produce goods and services in a more sustainable way by fostering innovation and upgrading the technological capabilities of the industry to make them sustainable with increased resource-use efficiency and greater adoption of clean environmentally sound processes.

2010 - Raw material Optimization Problem Identified

Textile & Leather being a natural product consumes large amount of water for its production. But the effective usage of material produced is not properly executed. We realized this problem andstarted working on the solution.

2014 - Gani Robotics Incorporated

Gani Robotics is incorporated and embarked on it’s robotics and industrial automation odyssey.

2015 - Nesting System Software development

Our strong point is the passion for innovation and from the very beginning we have been in the forefront of software development.

2018 - Recognized by DST, India

Our prototype GANICRP – Cut Resource planning system is continously refined and tested. We are recognised and awarded innovation grant Nidhi Prayas from Department of Science and Technology.

2019 -Top 10 Innovations in IIGP 2019

We are selected as Top 10 innovations in India Innovation Growth Programme 2019 and same year awarded purchase order from Tata International Limited, Dewas.

2020 - Gani Robotics exhibited in IILF 2019

We participated in India International Fair 2019 and garnered huge response from prospective customers.

2020 - GANICRP Installed in Tata International, Dewas

After a customization based in customer requirement, our GANICRP system is finally installed and given go ahead for production.

2021 - BAB, Virola, NMZ and more.

Gani Robotics fast expanding to other horizons. We participated in virtual fairs and did demo and trials for number of clients.

Gani Robotics follows a unique 4D approach comprising Discover, Design, Deliver and Dedicated Support for the optimization of your business.

Our Customers Gain

1

MONTHS ROI

1 %

MATERIAL OPTIMIZATION

1 %

INCREASE IN PRODUCTIVITY

1 %

LOW LABOR COST

Our Partners & Customers

Hear from our customers

“ During the time I have worked with SCG on this project, I have found Mike Campbell and his team to be highly knowledgeable and results-driven. Based on preliminary pilot testing and a strong understanding of subsurface. conditions, in particular fractured bedrock environments. ased on their work on this project. "

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada

“ For over 10 years working with SCG Industries on environmental contaminated sites they have continuously demonstrated excellent technical ability while ensuring superior customer service. Their collaborative approach and real time flexibility in adapting to changing conditions has contributed to the success of many project goals. “

Derek AuCoin

Defence Construction Canada